Plates

- tomsenior

- Feb 3, 2019

- 1 min read

Updated: Mar 19, 2019

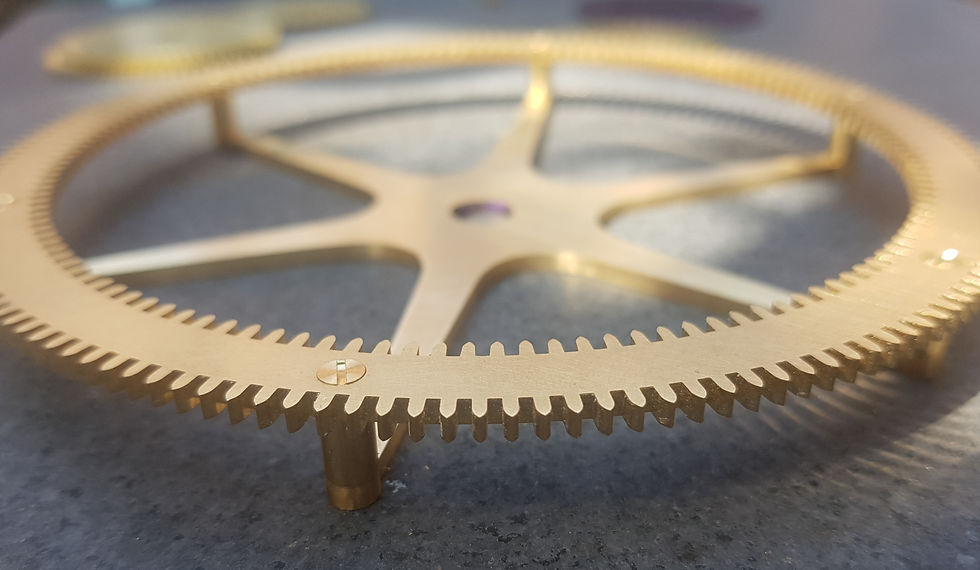

This section deals with cutting out the plates for the skeleton clock. This was a complicated process due to the small size of my bandsaw, forcing me to take some very tricky cuts to get the shape ready for finishing in the filing machine.

Comments