The Dial

- tomsenior

- Mar 19, 2019

- 1 min read

Updated: May 3, 2019

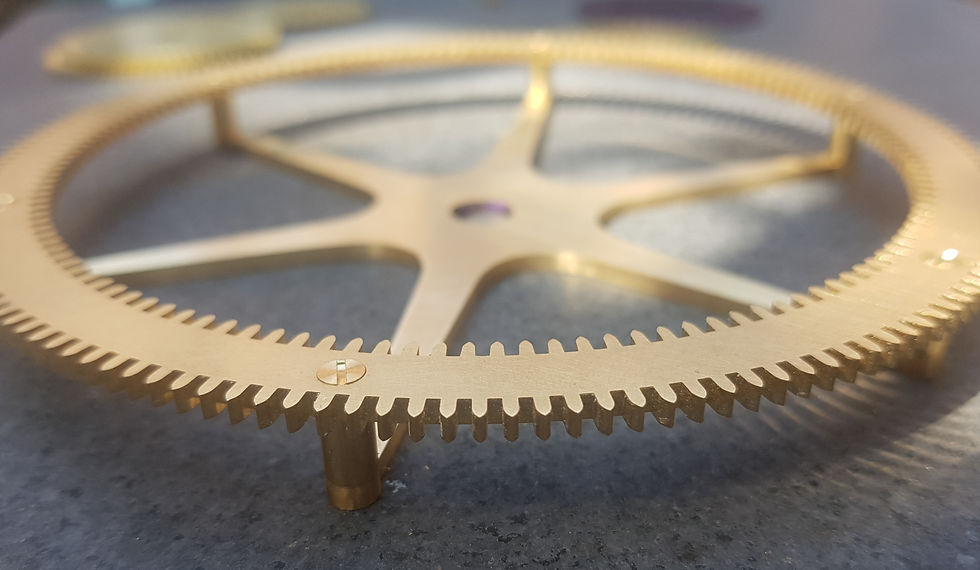

This section details the manufacture of the dial, using pre-purchased roman numeral figures. In crossing out the centre of the dial, I used my new Vallorbe needle and escapement files - which leave a perfect finish.

Comments