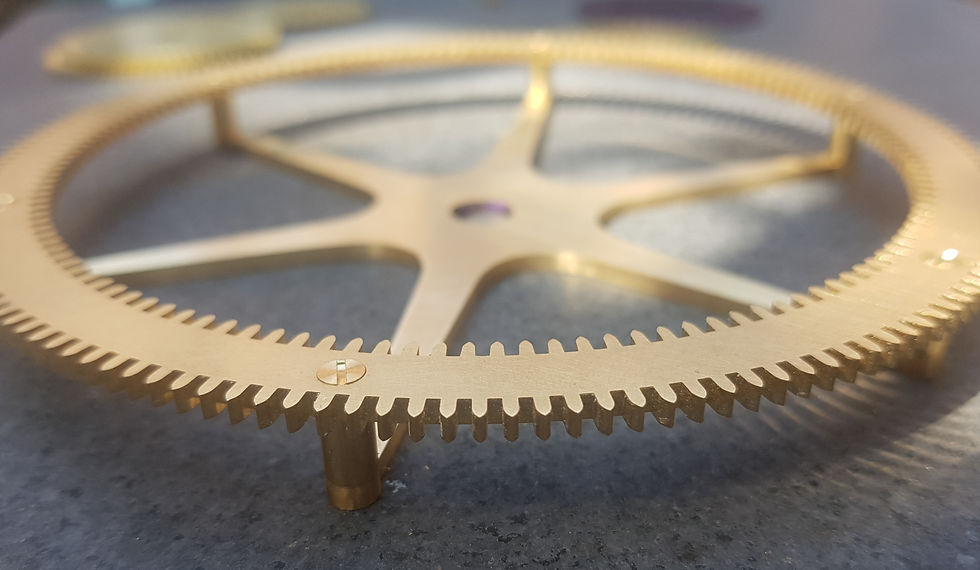

Fusee

- tomsenior

- Feb 3, 2019

- 1 min read

Updated: Mar 19, 2019

To create the fusee profile I disconnected the cross slide from its lead screw, to allow the groove cutter to precisely follow the profile of the fusee. It took about twenty passes (turning the lathe with arm power) to get the correct depth on the fusee groove.

Comments